- What is Gloss?

- What difference in gloss can a human see?

- Why Measure Gloss?

- How is Gloss Measured?

- How do I choose a Gloss Meter?

- Gloss Meter Configurations

- Gloss Meter by Industry

- Gloss Meter Industry Standards

Gloss Introduction

Gloss is an aspect of the visual perception of objects.

Gloss is the attribute of surfaces that causes them to have shiny or lustrous, metallic or matte appearances.

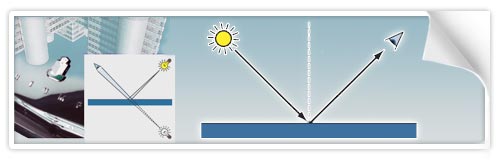

Gloss is a visual impression that is caused when a surface is evaluated. The more direct light is reflected, the more obvious will be the impression of gloss.

Gloss effects are based on the interaction of light with the physical properties of the sample surface. The other influencing component is the physiological evaluation scale. The human eye is still the best tool to evaluate gloss differences. However, the visual surface control is insufficient, because evaluation conditions are not clearly defined, and people see and judge differently.

In addition, the subjective perception of appearance is dependent on the personal experience: what is glossy for a paper manufacturer might be dull for an automotive maker. Gloss is measured by focusing on the reflected image and not by focusing on the surface. Eyesight and mood have a decisive role in the visual judgment. Also, important is what our eye is focused on. We evaluate a surface by focusing our eye on a reflected image of a light source. In order to guarantee a reliable and practical quality assurance it is necessary to define appearance with objective, measurable criteria. Accurate characterization of appearance does not only help to control quality, but improves quality and optimizes manufacturing processes.

High Gloss

Smooth and highly polished surfaces reflect images distinctly. The incident light is directly reflected on the surface, i.e. only in the main direction of reflection. The angle of incidence is equal to the angle of reflection.

Matte to Semi Gloss

On rough surfaces the light is diffusely scattered in all directions. The image forming qualities are diminished: A reflected object does no longer appear brilliant, but blurred.

The more uniform the light is scattered, the less intense is the reflection in the main direction and the duller the surface will appear.

2) What difference in gloss can a human see ?

If two different coatings are measured, what number of gloss units would be detectable by the human eye, how many units would be perceived as significantly different?

When measuring at 60 Degrees these detectable differences depend on the gloss level of the sample, for instance 3.0 GU difference measured on a very matte surface (perhaps 5GU), would be seen by the human eye but on a higher gloss coating (perhaps 60 GU) the difference would be very difficult to notice.

The only way that you can determine tolerances for your products would be experimentally, perhaps preparing printed samples at different gloss levels that you can show to end users of your coatings or internal "experts".

The other option is to change to a 20/60/85 degree instrument, the 85 degree glossmeter is more sensitive to differences in gloss below 10 GU @ 60° and the 20 Degrees has higher resolution on high gloss coatings (above 70 GU @ 60°). The advantage of using the three angles is that there is more equality to the gloss differences, in our experience a gloss difference of 5 GU, when measured with the correct geometry is just visible to a trained observer.

3) Why Measure Gloss ?

Gloss is an aspect of the visual perception of objects that is as important as color when considering the psychological impact of products on a consumer. In other words, "Gloss Sells" Gloss has been defined as the attribute of a surfaces that causes it to have a shiny or lustrous, metallic appearance.

The gloss of a surface can be greatly influenced by a number of factors, for example the smoothness achieved during polishing, the amount and type of coating applied or the quality of the substrate. Manufacturers design their products to have maximum appeal. Such examples are; highly reflective car body panels, glossy magazine covers or satin black designer furniture. Now what happens when products all of a sudden look different? Customers see this as a defect, or poor quality. Using a glossmeter and having good quality control practices eliminates this variable as a problem.

It is important therefore that gloss levels be consistent on every product or across different batches of products. Gloss can also be a measure of the quality of a surface, for instance a drop in the gloss of a coated surface may indicate problems with its cure- leading to other failures such as poor adhesion or lack of protection for the coated surface.

It is for these reasons that many manufacturing industries monitor the gloss of their products, from cars, printing and furniture to food, pharmaceuticals and consumer electronics. We also have Gloss Sensors used in process for real time gloss measurement. Please call us at 1-866-462-6832 to discuss the inline application.

|

|

CALL OUR EXPERTS TO DISCUSS YOUR APPLICATION OR ORDER TODAY! 1-866-462-6832

We have the lowest prices in North America Guaranteed! |

www.gloss-meters.com

owned by IMBOTEC GROUP your Gloss Meter experts