- How can I measure Small Surface areas with a Gloss Meter?

- How can I measure Irregular Surfaces using a Gloss Meter?

- How can I measure Gloss on a Curved Surface?

- How often should the instrument and standard tile be recalibrated?

- How often should I recalibrate my instrument?

- How do I clean my reference tile?

- Are there other Methods to Describe Gloss?

1) How can I Measure Small Surface

Areas with a Gloss Meter ?

An instrument has been used to resolve the gloss differences across holograms measure the polish on coins, steering wheels and extruded pipe work.

The Novo-Curve Gloss Meter has a very small measurement spot of 2mm that is used to measure the gloss of very small parts or resolve differences in gloss across small areas.

To get equivalent readings to a standard gloss-meter on surfaces that are slightly irregular it is recommended that the average value be taken of several readings.

2) How can I measure Irregular

Surfaces using a Gloss Meter ?

When irregular or textured surfaces are measured, the small measurement area can give different gloss values compared to a standard meter that has larger measurement area. To produce comparable results, take 10 measurements on the Novo-Curve Gloss Meter and use the statistic function to calculate the average reading.

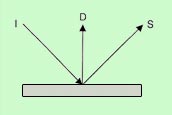

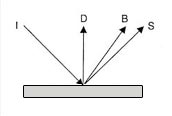

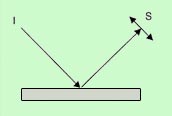

3) How can I measure the gloss of curved surfaces ?

All standard gloss meters are designed for flat surfaces, if they are used on a curved surface, the measurement beam is reflected away from the instrument detector resulting in incorrect readings. The more curved the surface the greater the error.

The solution to this problem is to using a very small area. The light is slightly scattered by the curved surface, however as long as the reflected beam remains sufficiently narrow to remain within the instrument detector the reading will be correct. The Novo-Curve Gloss Meter has been designed for this purpose and is specified for measuring cylinders and spheres with very low diameters. The Novo-Curve Gloss Meter was developed in conjunction with the National Physics Laboratory (NPL).

4) How often should the instrument and

standard tile be re-calibrated ?

It has been seen that standard tiles kept in optimum conditions can become contaminated and change up to 2 GU in three years.

Standard tiles used in "working" conditions will require regular calibration or checking.

A period of one year between tile re-calibration should be regarded as a minimum period. If a calibration standard becomes permanently scratched or damaged at any time it will require immediate recalibration or replacement.

The international standards state that it is the tile that is calibrated and traceable not the gloss-meter, however it is recommended thatthe instrument be also sent to an accredited service centre to verify its operation on an annual or bi-annual basis dependent on the operating conditions.

5) How should I recalibrate my Instrument ?

Gloss meters are very stable and will need infrequent calibration. To judge when a calibration is necessary simply place the gloss meter on its calibration tile and take a test reading. If the reading is less than 0.2 GU from the assigned calibration value for the tile re-calibration is not necessary.

6) How do I clean my Reference Tile ?

Novo Gloss (Rhopoint) standards are made of optical glass that is polished to the required gloss level. Samples should be handled with care, avoid touching the measurement face, wear gloves if appropriate.

Before calibration the tiles should be checked to ensure that they are clean and in good condition. If necessary the tiles may be wiped with a clean soft cloth moistened with warm soapy water, and dried with a lint-free cloth.

7) Are there other Methods to Describe Gloss ?